4 Easy Facts About Sheroz Earthworks Described

Right here's to the next 10 years! Web content created in association with Komatsu.

In the rapidly progressing world of building and construction, precision and efficiency are vital. 3D equipment control, a system that utilizes GPS and other sensors to lead machinery with identify precision, is revolutionising the sector - https://www.reverbnation.com/artist/sherozearthworks. From its very early days of 2D guidance, this technology has actually advanced dramatically, making jobs that when required hands-on treatment currently possible with very little human input

At the core of any kind of 3D device control system are GNSS receivers and antennas, recording satellite signals to establish the machine's precise location. Onboard computers and control boxes process this data and interact with the equipment.

Sheroz Earthworks for Beginners

This includes establishing up GNSS receivers, calibrating sensing units, and configuring the equipment control software - trimble gps. The magic of 3D equipment control lies in its real-time data collection and handling.

Customer user interfaces supply real-time updates on the equipment's position and needed adjustments, making certain accurate control. Several aspects affect precision, consisting of satellite signal top quality and sensing unit calibration. Techniques like Real-Time Kinematic (RTK) positioning and Accurate Point Positioning (PPP) enhance precision, making sure the highest possible accuracy. In building, 3D maker control is used for earthmoving, grading, paving, and excavation, guaranteeing jobs are completed to precise requirements.

The Only Guide for Sheroz Earthworks

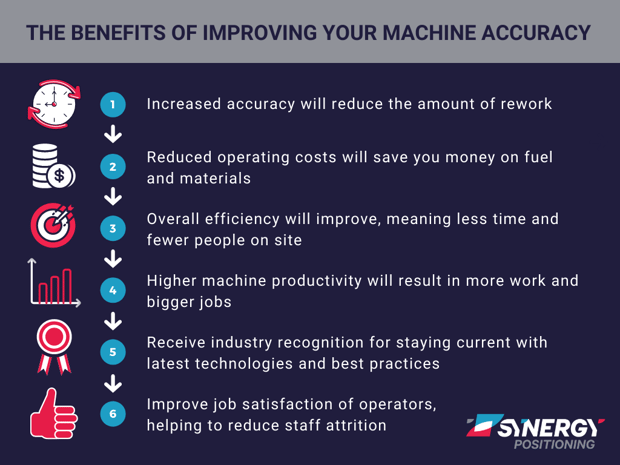

3D device control substantially increases efficiency by decreasing rework and reducing material wastage, resulting in much faster and extra cost-effective project completion. The innovation ensures every task is executed specifically as planned, resulting in continually high-grade job. One of the most engaging benefits of 3D equipment control is the substantial expense financial savings it supplies.

Gas intake is optimised because makers operate a lot more efficiently and stay clear of unnecessary activities. By reducing human mistake and restricting exposure to unsafe environments, 3D maker control enhances worker safety and security and minimizes crashes.

From building to mining, this modern technology guarantees jobs are implemented accurately and safely, lowering costs and enhancing results. As developments proceed, the possibility for 3D equipment control to further enhance performance and security grows. Welcoming this modern technology is vital for sector professionals wanting to remain affordable and attain the highest criteria in their tasks.

Getting The Sheroz Earthworks To Work

Discover the future of precision and performance currently! Also, take a look at our latest YouTube video clip on the FJD H36 Motor Grader Control System to see the innovation in activity: View now.

Over the years, we've seen drivers with great deals of experience do some impressive points with their makers. Possibly they have an eye for changes that boost precision, or probably they understand which attributes of their equipment to make use of and when to improve performance or performance - https://linktr.ee/floydoverbeck4500. Yet with today's advancements in heavy devices technology, even proficient drivers can take advantage of a real-time help to boost their day-to-day performance (trimble parts).

This is where machine control systems factor in. Some excavators come with maker control systems that assist the operator through functions to automate the digging process.

Sheroz Earthworks Can Be Fun For Anyone

With this included accuracy, rework is practically eliminated, permitting the operator to complete the job promptly and relocate to the following task. For those working with harmful or hard jobsites, remote-controlled solutions open brand-new possibilities. This impressive add-on allows you to operate an excavator from a distance in locations with dangerous substances (like in a potash mine) or bad ground problems (like mud).

Device control systems offer important advantages to even more than simply excavator drivers. If you have check out this site a truck come in with a target of 23 bunches, your operator can fill their pail and dynamically evaluate itoften without also being stationary.

This indicates the operator can see the precise weight of the lots they're about to unload (topcon laser levels). On-board considering supplies real-time understanding right into the pail's tons to make overloading, underloading, reweighing and waiting times a distant memory. Volvo Building and construction EquipmentIf they dump 12 bunches on the first pass, the next pail requires to evaluate 11 lots

Some Ideas on Sheroz Earthworks You Should Know

A lot of procedures utilize an on-board considering app to make sure that the tons is accurate before they send their vehicles to the ranges, which is essential due to the fact that the scale weight is what's used for billing and invoicing functions. Several producers consist of some kind of evaluating program on their loaders. Some likewise have features that permit firms to monitor and control the total loads of multiple vehicles.

Comments on “Get This Report about Sheroz Earthworks”